Ultra-V Connect™

Ultra-V Connect™ is a high-intensity rapid decontamination technology created by Inivos to prevent and control infection in health spaces and keep patients and staff safe.

Ultra-V Connect™

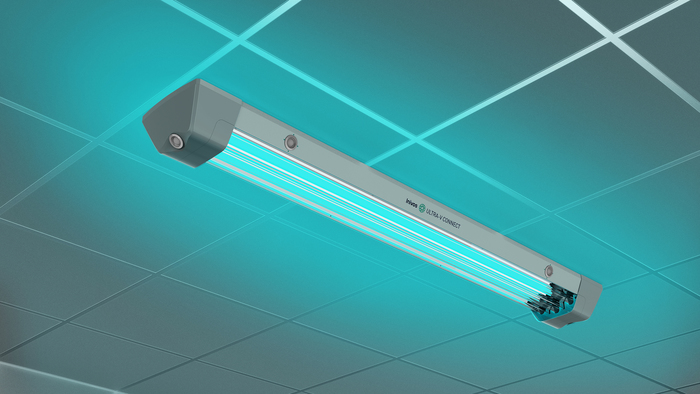

Every Ultra-V Connect system or systems are designed to be able to provide a variety of validated processes in any given room or environment. For example, within a side room the system can be set to have specific targeted decontamination cycles for the whole room, the patient bed only, bed and bedside chair and so on. This provides excellent flexibility and can shorten turnaround times.

Locations, layouts, zoning and custom decontamination cycles are planned, mapped out and configured based on understanding your needs. All of this is delivered in a system which takes out the hard work for you. All custom process can be safely actioned on-demand via the wireless user monitor location outside the treatment area or areas. This proven technology, which is used by healthcare around the world, has been independently validated.

Ultra-V Connect™ installation

Intuitive Operation

Ultra-V Connect™ validated assurance

Intelligent reporting

Information on each cycle is delivered direct to your inbox. An email is automatically generated after the process has been completed which contains a report on the decontamination cycle. This provides a robust audit trail and security in the efficacy of Ultra-V Connect.

Spectrome™ Monitoring

Routine calibrations are a key part of our ongoing service level agreements. These ensure the process cycle times are correct and concur with those originally set up for each system. This ensures efficacy of the system is maintained and recorded.

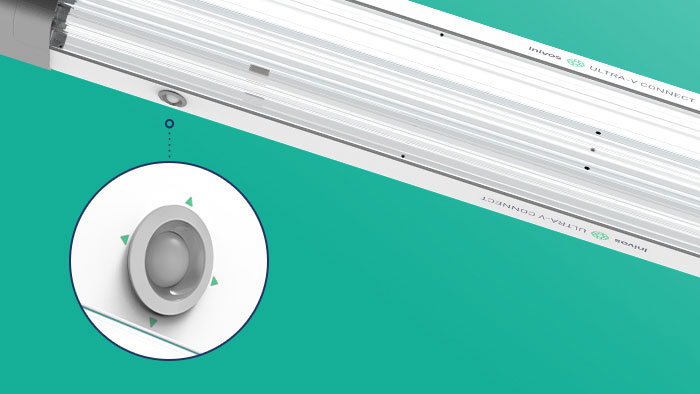

Reducing the Risk

The integrated passive infrared sensors (PIR sensors) mean Ultra-V Connect can detect entry into the room and automatically interrupt the decontamination process. For effective safety the PIR sensors are positioned to achieve full coverage of its environment.

Chemical Free

Ultra-V Connect™ has been designed to work without the use of chemical compounds in its decontamination. This removes any potential risks and environmental problems associated with biochemical disinfection devices.

Fast and Efficient

Ultra-V Connect™ is designed to decontaminate small rooms in as little as eight minutes. The room can be re-entered immediately after the completion of its cycle meaning no down time is required before it can be used again.

Disinfection Robots